Collection System

The sanitary sewer collection system is a critical asset of the City of Norwalk’s infrastructure. Designed to collect and convey wastewater to the wastewater treatment plant, collection systems are a key element in an effective wastewater system.

Service Area:

- Serves 80% of the City’s population

- Town of Wilton ~ 4% of total flow

- Town of Westport (11 customers)

Sanitary Sewer Collection System Facts:

- Gravity mains ~205 miles (6” to 72” diameter)

- Gravity assets ~6,500

- Manholes ~6,400

- Force mains ~6.7 miles

- Major siphons – 2 locations

Operations and Maintenance (O&M)

On September 16, 2019, the City and Veolia Water Contract Operations USA, Inc. (Veolia) entered into a 10-year Wastewater Treatment System Service Agreement for operations, maintenance, and management of the City’s wastewater treatment system. Veolia began operating the system on May 17, 2020. Under the agreement, Veolia is responsible for the O&M of the sanitary sewer collection system, including pump stations, force mains, pipes, siphons, and related manholes (MHs) and collection system appurtenances. Veolia developed an O&M program to optimize human and material resources to provide an efficient and dependable collection system for the City of Norwalk.

The Veolia Team utilizes equipment including closed-circuit television (CCTV) inspection camera truck/trailer, CCTV camera equipment, recording media, jetting/vacuum trucks, metal detection devices, wrenches, and assorted hand tools for maintenance of the collection system. The jetting/vacuum trucks (also known as the vactor trucks) are used to pressure wash and vacuum debris from manholes and sewer mains.

CCTV Camera Truck

Vactor Truck

Closed-circuit television (CCTV) inspection

CCTV inspection is the process of inserting a camera into the sewer pipe and recording footage for visual inspection. CCTV inspection footage is used to identify obstructions such as invasive tree roots, grease build up, and cracks or breaks in the piping. CCTV inspection videos are recorded for future reference. The WPCA has included CCTV inspection in its O&M agreement with Veolia, which includes a minimum of 2 miles per month of CCTV inspection. The Veolia team utilizes a mobile CCTV camera that is equipped with wheels that can be steered through the pipe.

Inspection Process

CCTV Mobile Camera

Veolia Team performing CCTV inspection and reviewing camera footage

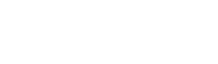

Sewer Line Rapid Assessment Tool (SL-RAT)

SL-RAT is a portable onsite assessment tool that uses acoustics to detect blockages in the sanitary sewer collection system. It has two components: the transmitter and the receiver. The transmitter sends an acoustic signal down the pipe and the receiver interprets the acoustic signal. SL-RAT provides an assessment on a scale of 0-10 indicating if there is build up or an obstruction in the pipe. The WPCA has included SL-RAT inspection in its O&M agreement with Veolia as it is a cost-effective method of determining the condition of the sanitary sewer collection system and allows resources to be focused on targeted problem areas.

SL-RAT Assessment Tool

SmartCover Technology

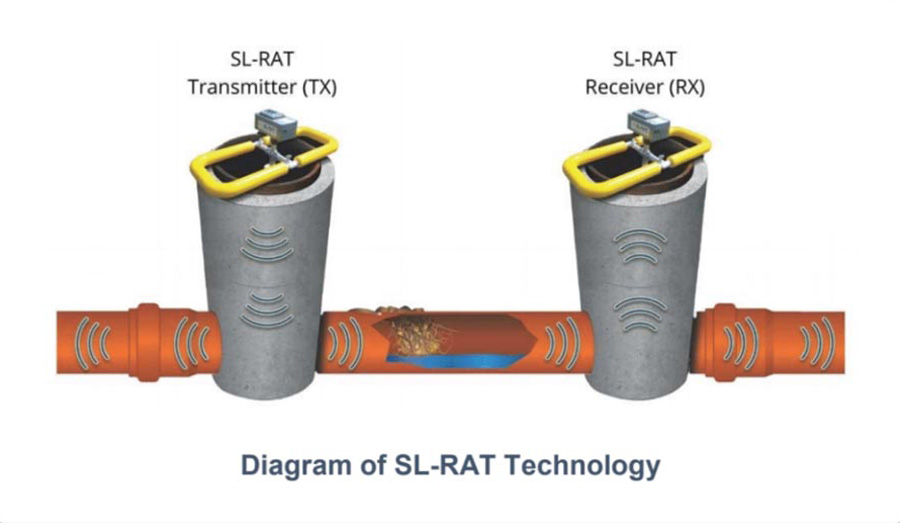

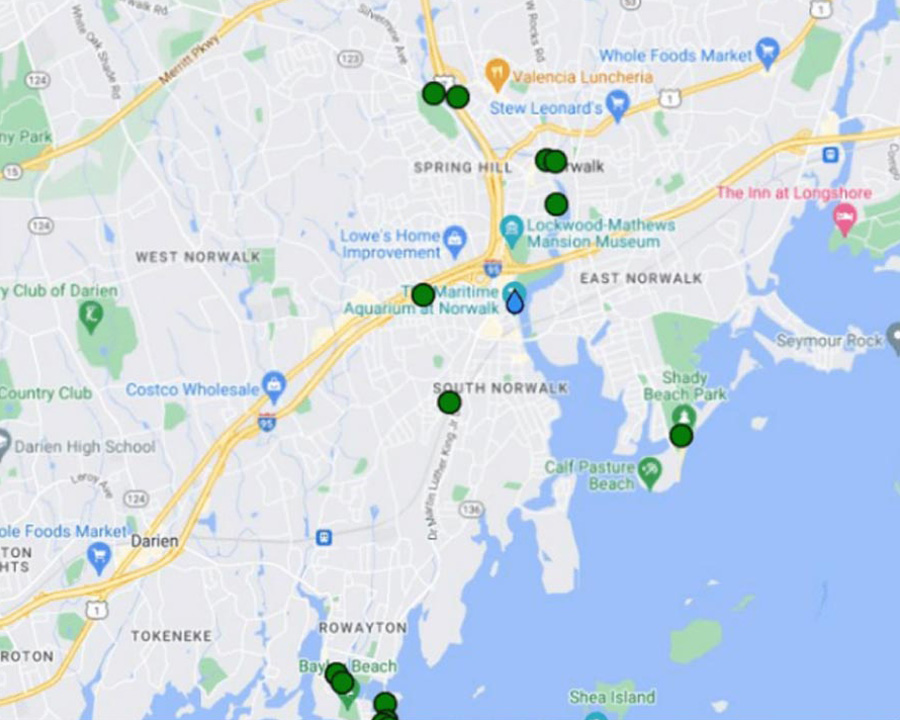

SmartCovers are manhole monitoring tools that are used to track parameters such as water level, flow, and temperature. They can be programmed to generate alarms and notifications. SmartCovers sensors have been installed at 14 select sanitary manhole locations in the collection system. The Veolia team uses the SmartCover technology to get real-time data and alarms on sanitary sewer overflows. They use the information to resolve issues and get an understanding of trends in the data.

City of Norwalk SmartCover Locations

Example SmartCover Data: Water Level vs. Time

Inflow and Infiltration (I&I)

Inflow is stormwater that enters the sewer system through rain leaders, yard drains, sump pumps, defective manhole covers, or cross connections with the storm system. Infiltration is groundwater that enters the sanitary sewer collection through defects in pipes and manholes or deteriorating pipe joints.

Collection System I&I Elimination

There are various methods that can be used to identify and eliminate I&I such as closed-circuit television (CCTV) inspection, dye testing, smoke testing, cured-in-place-pipe (CIPP) lining, point repairs, and sealing of manholes. These practices are essential to the proper maintenance of the collection system. The WPCA engages Veolia under its operations and maintenance (O&M) agreement as well as other consultants to perform this work to improve the condition of the City’s sanitary sewer collection system.

Manhole Rehabilitation

Before/After

Before/After

Excavation Pipe Repair

Deformed or broken pipe replaced with PVC pipe

Dye Testing

Dye testing is used to determine the presence of illicit connections or sources of I&I entering the sanitary sewer system. The process consists of introducing non-toxic dye at a designated location and having field staff check the downstream manhole or cleanout to see if the dye is visible. The path of the dye is documented and leaks into the sewer system or interconnections with the storm system are located.

Smoke Testing

Smoke testing is performed to determine the presence of illicit connections or sources of I&I entering the sanitary sewer system. The WPCA distributes notifications to residents and stakeholders 7 days and 24 hours prior to smoke testing.

The process of smoke testing involves blowing non-toxic smoke into a manhole. The smoke travels through the collection system and exits at any surrounding properties that are connected within the testing area.

Smoke can be seen coming out of roof vents, manholes, and downspouts.

Once these locations where smoke is identified are documented, recommended disconnection and rehabilitation methods can be determined.

Cured-in-place-pipe (CIPP) Lining

CIPP lining is a trenchless method of sewer pipe rehabilitation that aims to repair and restore the existing pipe. The process involves inserting a polyester or fiberglass tube that is saturated with resin into a pipe. Once the tube is properly placed and inflated it is cured using heat or ultraviolet light. Specialty companies are engaged in the design and installation of the system. CIPP lining creates a protective layer in the pipe and protects against infiltration and obstructions such as tree roots.

It is beneficial as it increases the life span of the pipe asset by 50+ years and is cost-effective as it does not require open-cut excavation. The WPCA has conducted lining projects on 67,000 feet of sewer mains, representing approximately 6.2% of the total collection system.